In the ever-evolving world of pharmaceutical manufacturing, quality control plays a pivotal role in ensuring the safety and efficacy of products. With stringent regulations and high demand for precision, the industry has increasingly turned to cutting-edge technologies like machine vision systems to meet its needs. YB Systems, based in Paterson, NJ, is a leader in this space, providing advanced visual inspection and automated tray counting solutions specifically designed for pharmaceutical production lines. But how exactly does machine vision tech tackle common quality control challenges?

Machine Vision Tech: Revolutionizing Pharmaceutical Quality Control

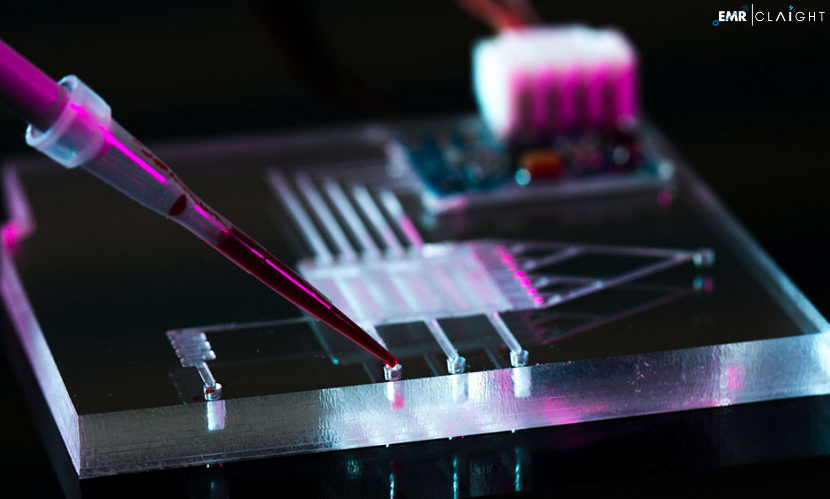

At its core, machine vision tech refers to the use of automated cameras, sensors, and algorithms to visually inspect products for defects, count items accurately, and ensure that manufacturing processes meet required standards. Pharmaceutical production lines, in particular, benefit immensely from this technology, as it can handle tasks with unparalleled speed and precision.

Traditional inspection methods, often reliant on human intervention, are prone to errors, fatigue, and inconsistency. In contrast, machine vision systems, like those offered by YB Systems’ Counse, are designed to operate around the clock without compromising quality. This shift towards automation addresses a variety of issues that pharmaceutical manufacturers frequently encounter, ensuring that every tablet, capsule, or vial meets the industry’s high standards.

Improving Accuracy with Machine Vision Tech

One of the most significant challenges in pharmaceutical manufacturing is achieving accurate and consistent inspections. Human error can result in missed defects, incorrect counts, or contamination risks, all of which can have serious consequences for product safety and regulatory compliance. Machine vision tech eliminates these concerns by using sophisticated algorithms to analyze products in real time.

For instance, YB Systems’ Counse system is equipped with high-resolution cameras and sensors that can detect even the most minute deviations in product quality. Whether it’s ensuring the correct number of tablets in a blister pack or checking the integrity of vial seals, machine vision systems can do it with an impressive degree of accuracy. This leads to fewer recalls, reduced waste, and a more efficient production process overall.

Enhancing Efficiency and Reducing Downtime

Time is money in pharmaceutical manufacturing, and even a brief period of downtime can significantly impact a company’s bottom line. Traditional quality control methods can be time-consuming, requiring manual inspections that slow down production lines. Machine vision tech, on the other hand, operates at high speeds and can inspect thousands of units in a fraction of the time it would take a human inspector.

This enhanced efficiency is particularly beneficial in high-volume production environments. Automated systems like YB Systems’ tray counting solutions can handle large batches of products without the need for frequent stops or recalibrations. By streamlining the inspection process, manufacturers can maintain continuous production, reduce bottlenecks, and ultimately deliver products to market faster.

Ensuring Compliance with Industry Regulations

Pharmaceutical manufacturing is subject to some of the most stringent regulations in any industry. Products must be manufactured, packaged, and labeled according to precise specifications to ensure patient safety. Machine vision technology plays a critical role in ensuring that these standards are consistently met.

For example, YB Systems’ advanced visual inspection systems are designed to detect any deviation from regulatory guidelines, whether it’s an incorrect label, a defective blister pack, or a vial with an improper fill level. By catching these issues before products leave the factory, manufacturers can avoid costly fines, recalls, and damage to their reputation.

Tackling Contamination and Product Integrity Issues

Contamination is a major concern in pharmaceutical manufacturing, where even a small lapse in quality control can result in a product being unsafe for consumers. Machine vision systems can be programmed to identify signs of contamination or defects that could compromise the integrity of a product. This could include detecting particles within a vial, cracks in the glass, or faulty packaging seals.

YB Systems’ Counse system is particularly adept at ensuring product integrity by scanning each unit in real-time and flagging any that don’t meet preset quality standards. The system’s ability to identify potential risks early in the process means that contaminated or defective products are removed before they can reach patients, safeguarding both the manufacturer’s reputation and consumer health.

Reducing Waste and Increasing Sustainability

Pharmaceutical companies are increasingly focused on reducing waste and adopting more sustainable practices. Machine vision technology supports this goal by improving the efficiency and accuracy of quality control processes. By identifying defects or issues early, manufacturers can reduce the number of products that need to be discarded due to quality failures.

In addition, machine vision systems minimize the need for rework, further reducing waste. This is particularly important in pharmaceutical manufacturing, where reprocessing or remanufacturing products can be costly and time-consuming. Automated inspection systems like those offered by YB Systems ensure that only products that meet exacting standards are approved, leading to a more sustainable production process.

Customizable Solutions for Unique Manufacturing Challenges

No two pharmaceutical manufacturing lines are exactly alike, and quality control solutions must be tailored to address the specific needs of each operation. One of the key advantages of machine vision tech is its flexibility. Systems can be customized to inspect products of varying sizes, shapes, and formulations, ensuring that manufacturers can maintain high standards of quality regardless of the specifics of their production line.

YB Systems offers a range of customizable machine vision solutions, including the Counse system, which can be adapted to meet the unique requirements of each client. Whether a company needs to inspect injectable vials, blister packs, or bulk tablets, YB Systems can develop a solution that fits seamlessly into their existing production line.

Conclusion: Why Machine Vision is the Future of Pharmaceutical Quality Control

As pharmaceutical manufacturing becomes more complex and the demand for high-quality, safe products continues to rise, machine vision technology is emerging as a critical tool for maintaining rigorous quality control standards. Systems like those developed by YB Systems offer manufacturers the ability to inspect products with unparalleled accuracy, efficiency, and consistency, all while reducing waste and ensuring compliance with stringent industry regulations.

With its ability to automate inspections, enhance product integrity, and reduce costs, machine vision tech is poised to revolutionize the pharmaceutical industry. Companies that adopt this technology will not only improve their production processes but also ensure that they continue to deliver safe, high-quality products to consumers around the world.